Large amounts of resources and energy are used in galvanized sheet production which likewise generates vast amounts of pollutant emissions.

Galvanized metal sheets manufacturing environmental impact.

Dangerous chemicals the process to fabricate sheet metal uses different solvents surface treatments cutting agents and more.

Greenhouse gas emissions from steel production.

Tons of co2 emitted into the atmosphere.

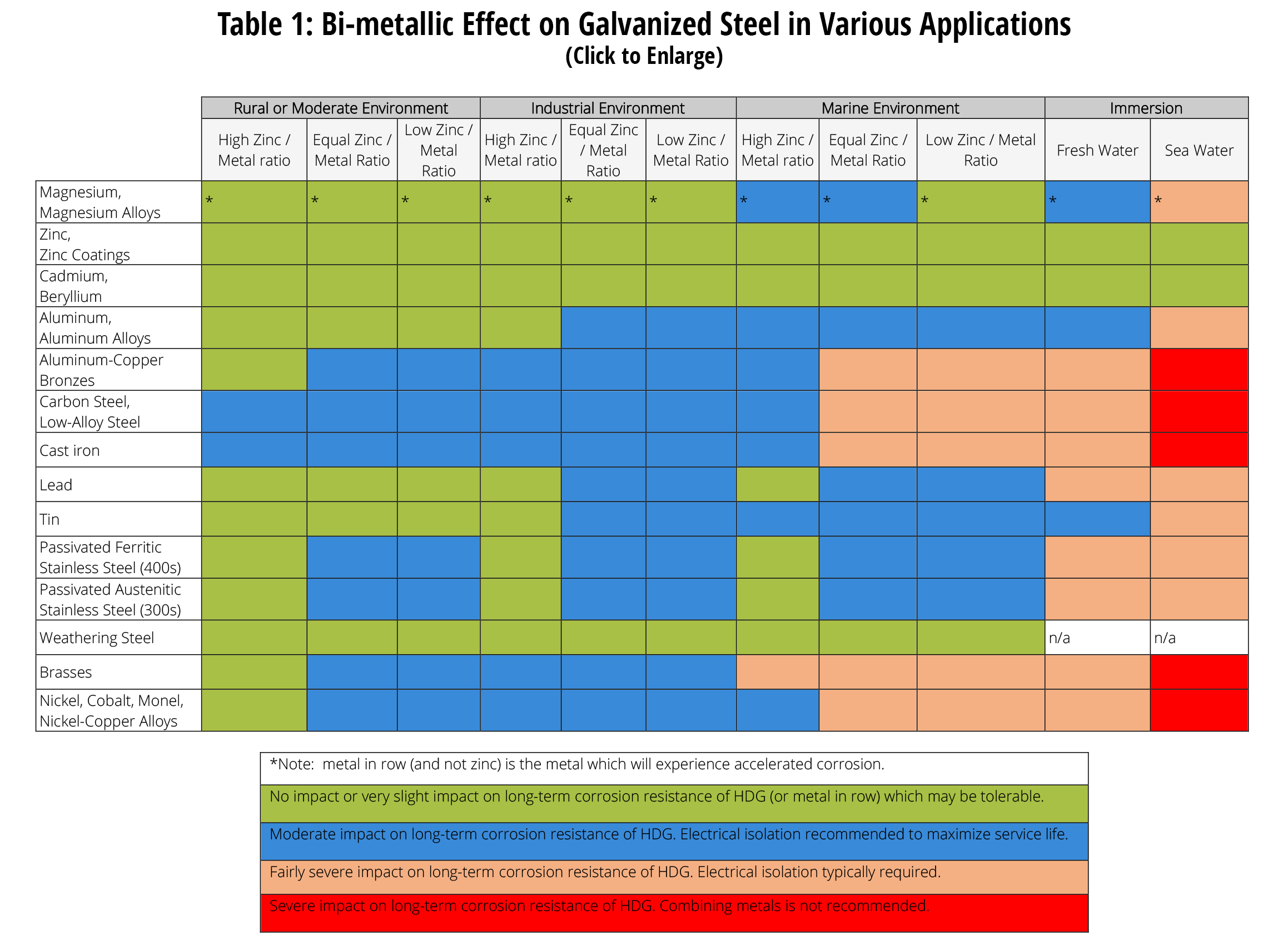

The corrosion behavior of the galvanized coating in various atmospheric environments is influenced by many factors such as prevailing wind direction type and density of corrosive fumes and pollutants amount of sea spray number of wetting and drying cycles and the duration of exposure to moisture.

Corrosion also known as rust is a natural process that occurs when steel is exposed to the environment.

The rain barrel shown here is tucked into a front yard and has an industrial contemporary look among drought tolerant plants.

These chemicals are often toxic so they are hard to work with and difficult to dispose of.

2010 compared the proportional impacts of different steel products slab hot rolled cold rolled hot dipped galvanized and electro galvanized steels in the categories of fossil fuels global warming potential ecotoxicity minerals carcinogens and respiratory inorganics and indicated that the hot dipped galvanized steel is with the highest impacts.

In a comprehensive study tongpool et al.

In the face of the rapid growth of the production and demand of galvanized sheet in china it is very important to find out the key factors of the environment impact in the production of galvanized sheet.

Metal is a common material for rainwater harvesting practices because when galvanized it resists mold and rust.

When properly installed these panels will shed rain and eliminate ponding water.

Every year steel corrosion costs the economy around 2 2 million 1.

Galvanized sheet is the most widely used coated steel plate globally in the industry of construction automobile electronics manufacturing etc.

This can create environmental hazards within the manufacturing plant and within the community.

Galvalume substrates are coated with an alloy of zinc plus aluminum.

Galvalume has two to four times the corrosion resistance of galvanized steel even in harsh environments.