When you are looking at frozen yogurt machines you may notice that some are air cooled and others are water cooled so to clear up any confusion i am going to talk a little bit about the differences between the two types and how to know which is a better fit for your frozen yogurt shop.

Glycol cooling system frozen yogurt.

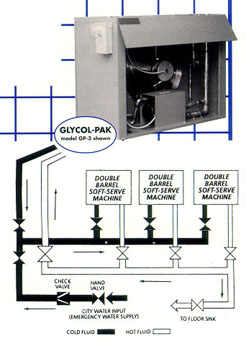

The hot glycol from the water cooled condenser is piped to the glycol pak fluid cooler whereby heat is removed from the fluid and rejected into the.

Glycol is a mixture of water and ethylene glycol.

Fluid cooler is a heat exchanger designed to operate with water cooled dispensing equipment.

We intention to create far more value for our buyers with our loaded resources state of the art machinery experienced workers and great expert services for glycol cooling system frozen yogurt glycol cooling system frozen yogurt glycol cooling system we only supply quality products and we believe this is the only way to keep business.

Glycol correction factors all heat exchangers experience a capacity loss when the fluid is a higher specific gravity than water glycols are heavy syrup like fluids at full concentration and become thinner when mixed with water.

Cold shot chillers frozen yogurt machine glycol chiller system options to compliment the water chiller low ambient kit to 20f usda food grade propylene glycol condenser coil coating ez clean filters line phase monitor protection flow meters spare parts kit labor warranty.

Fluid cooler is a heat exchanger designed to operate with water cooled dispensing equipment.

And yes it is like it sounds it used air.

Engineered to provide water cooling to ice cream and frozen yogurt machines.

American chillers offers a full line of chillers specifically designed to cool ice cream and yogurt machines like the stoelting brand machines.

Fluid cooling systems for soft serve frozen yogurt freezers.

Fluid cooling systems for soft serve frozen yogurt freezers.

3 to 20 nominal tons.

Closed loop recirculating chillers.

This type of refrigerant is similar to antifreeze found in an automobile.

However the mixed solution of water glycol will be thicker heavier than the water alone was.

Let s start with the air cooling.

A glycol chiller and pump is usually installed on the roof of the building and recirculates food safe glycol through the.

The hot glycol from the water cooled condenser is piped to the glycol pak fluid cooler whereby heat is removed from the fluid and rejected into the.

Glycol cooling systems are one of the best long term solutions to eliminate water usage for ice cream machines.

This system uses a small heat exchanger to collect heat from a type of refrigerant.

Fluid cooler is a heat exchanger designed to operate with water cooled dispensing equipment.

It is an expensive upfront investment but the usual roi is under a year and then the savings really rack up.